SPOT ON

A project aiming to lower the barrier to entry for newbies to electronics prototyping by making soldering simpler and safer.

January - June 2019

Group Project with Mark Ridge, Felix Murray and Max Stevensen

A project aiming to lower the barrier to entry for newbies to electronics prototyping by making soldering simpler and safer.

January - June 2019

Group Project with Mark Ridge, Felix Murray and Max Stevensen

There is a clear rise in the popularity of hobbyist electronics projects as electronics becomes more prominent in the world around us, especially those for children. We also spotted a decline in the teaching of valuable practical skills for our modern society in UK schools.

We set about finding out what practical skills were on the decline but might be extremely valuable to learn in an electronics centred world.

Soldering was identified due to it's 'underratedness' in its usefulness for repairing and prototyping and it's high barrier to entry due to safety concerns from parents and a potential uneasiness with a lack of knowledge in the area.

Therefore the goal for spot-on was simple. Aim to lower the barriers to entry for new entrants to electronics prototyping by developing a hand tool and accompanying ecosystem that is user friendly and reduces the perceptions of danger and difficulty.

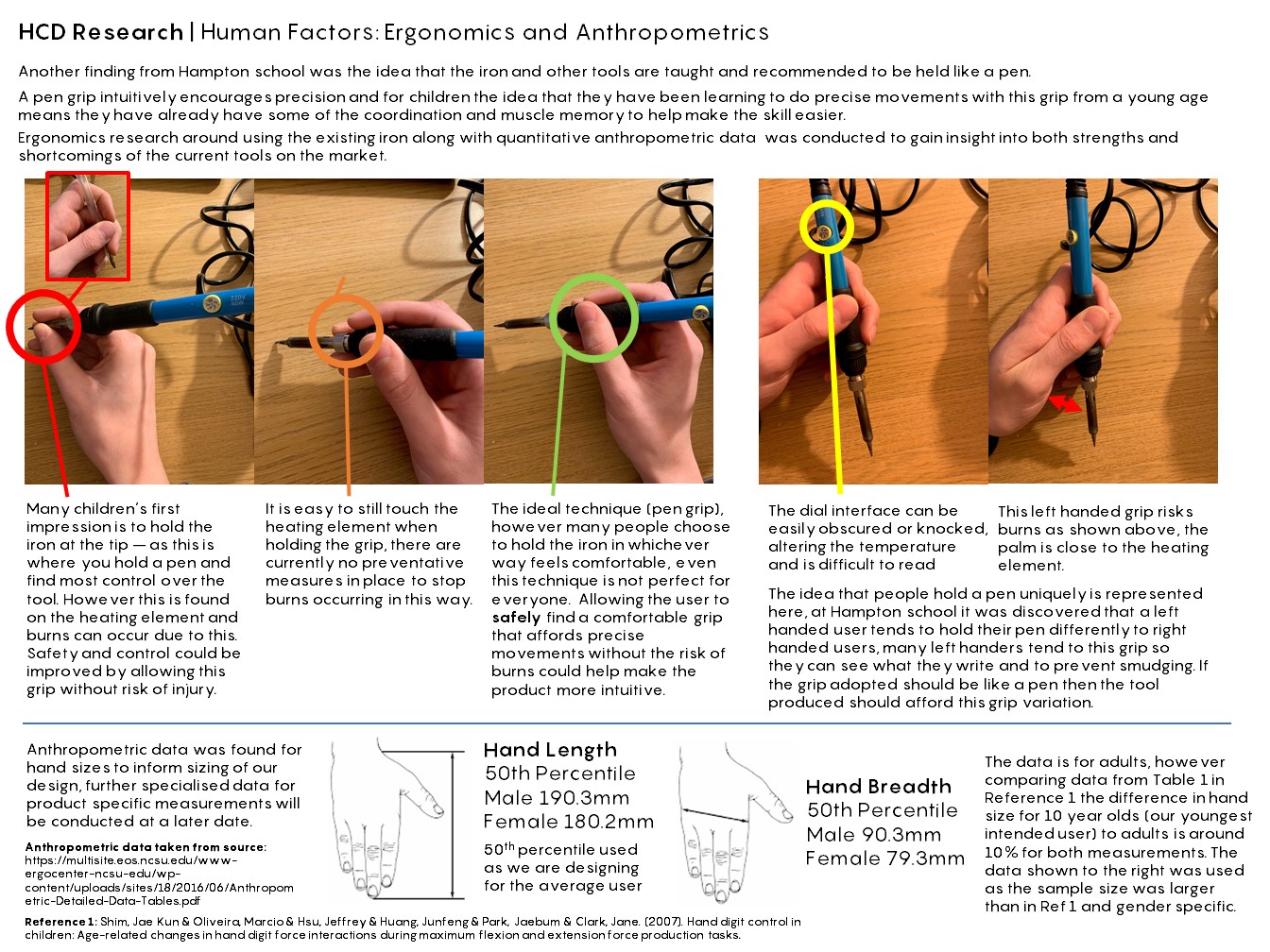

HCD research into soldering was conducted through primary means. Visits to secondary schools and interviews with teachers and parents revealed many insights.

1. The perceived danger of soldering is mainly psychological - the most common injury is a first degree burn - surprisingly to the hand holding the solder, not the iron. Second/third degree burns are extremely rare. The large exposed area of hot metal on a traditional soldering iron contributes to this.

2. Parents usually have to approve purchases for children, designing for parents attitudes could improve accessibility.

3. We can learn from industrial hand soldering practices, simplifying the task might improve appeal, especially for children, where motor control for precise movement hasn't fully developed yet.

4. 3D printing pens and hot glue guns are extremely popular with children, however they both can cause the same injuries as soldering - taking inspiration from the marketing and design of these products could contribute to a more appealing concept.

Using our insights from the previous stage we conducted broad ideation, which narrowed to a range of concepts for an assistive soldering tool.

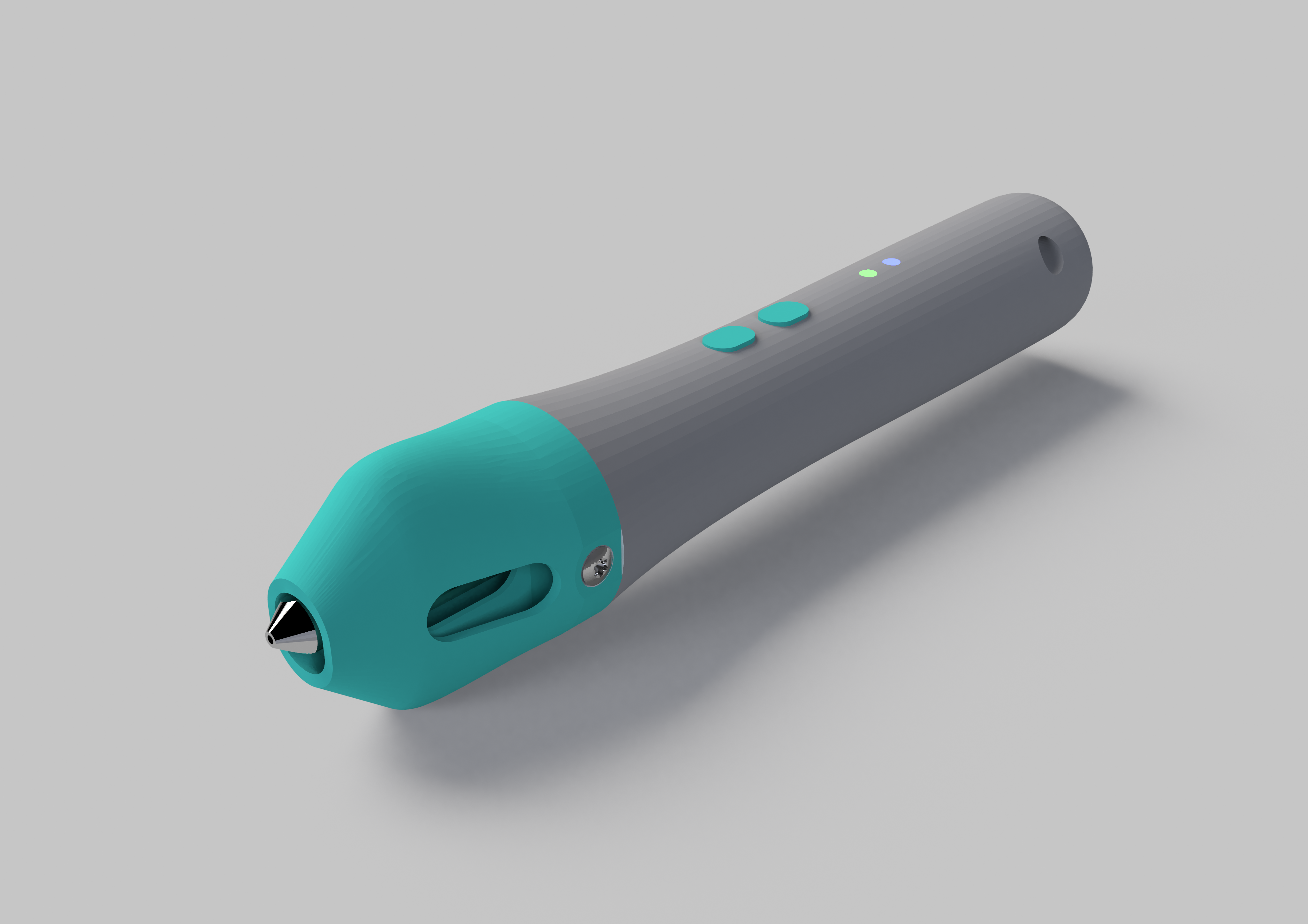

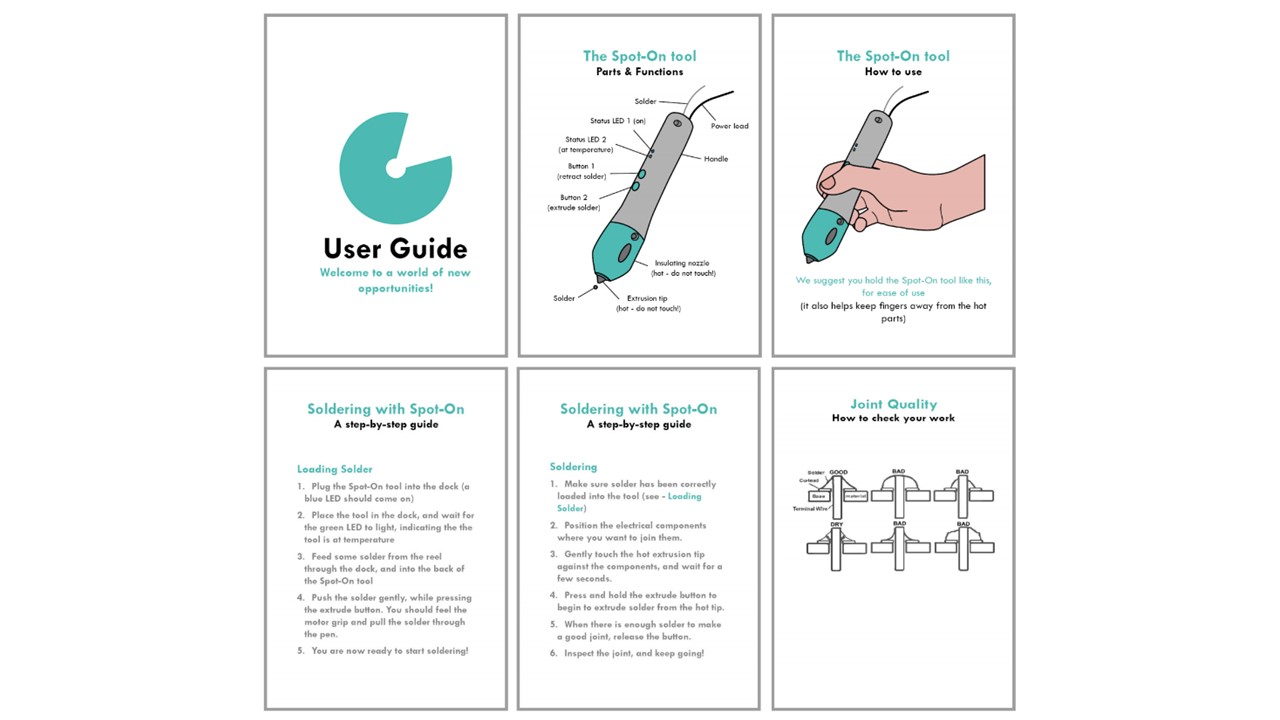

We came to the conclusion that the best proposal that encapsulated all of our findings was to create a pen that could extrude the solder, and melt it at the joint, and could be used with one hand, freeing up the second. It would also reduce the size of the exposed hot area and reduce the risk of injury. It's pen shape would make it intuitive to use.

We then began prototyping and testing, to ensure the idea was viable, and then iterating and developing the products various features to create a final proposal and prototype.

The images to the right show the culmination of our prototyping and testing.

The next steps for the project would be to produce a slightly higher fidelity working prototype by improving the quality of some electronic components (no more handmade PCB's!). We would then aim to continue to develop the product to a production level and then test its market potential.

During the production of the final proposal we allocated more specific roles to suit our capabilities.

It was my role to develop much on side of the product itself, working on the aesthetics and ergonomics of the product to promote safety and ease of use. I assisted with the testing of the electronics and production of the hot-end. I also worked on the design the fixtures and fittings for the internals and informed material selection choices. I aided in manufacturing our prototype and the development of the product through iterating in CAD (Solidworks). To be a part of the design and development of this product has been amazing and I looked forward to working on similar projects!